Dipylon-style amphorae: Technological specialisation for elite consumption

Introduction

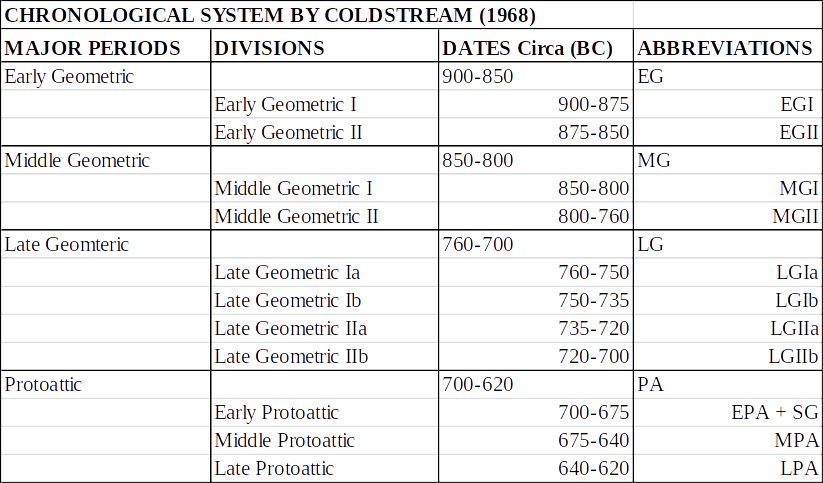

This article has been inspired by a paper I presented in June 2018, during the conference ‘Exploring Specialisation through Ceramic Technology and Use’, organised by the Ancient Ceramics Study Group and the McDonald Institute for Archaeological Research in Cambridge. The paper is inspired by my PhD thesis, which is titled: “The correlation of technological and stylistic changes, and society, in the production of Attic Geometric and Orientalising finewares”. During my doctoral research, I demonstrated the degree of standardisation in the production of Attic Early Iron Age amphorae across two centuries, covering the Early, Middle and Late Geometric periods, between circa 900 and 700 BC. In this paper, I will be talking about a distinct and highly specialised product of the Attic Early Iron Age, the Dipylon-style amphora. Before doing so, I will present some background information on pottery consumption during the aforementioned period.

Pottery consumption in Geometric Attica

The Attic Geometric period has been named after a distinct pottery style produced in Athens between circa 900 and 700 BC.

It is divided in the Early Geometric period, during which the main burial rite for adults is inurned cremation, accompanied by the use of ceramic burial markers. This is followed by the Middle Geometric period, which is characterised by elaborate cremation burials, rich in ceramic artefacts. Finally, the Late Geometric period, which is characterised by important changes in burial rites and the consumption of funerary pottery.

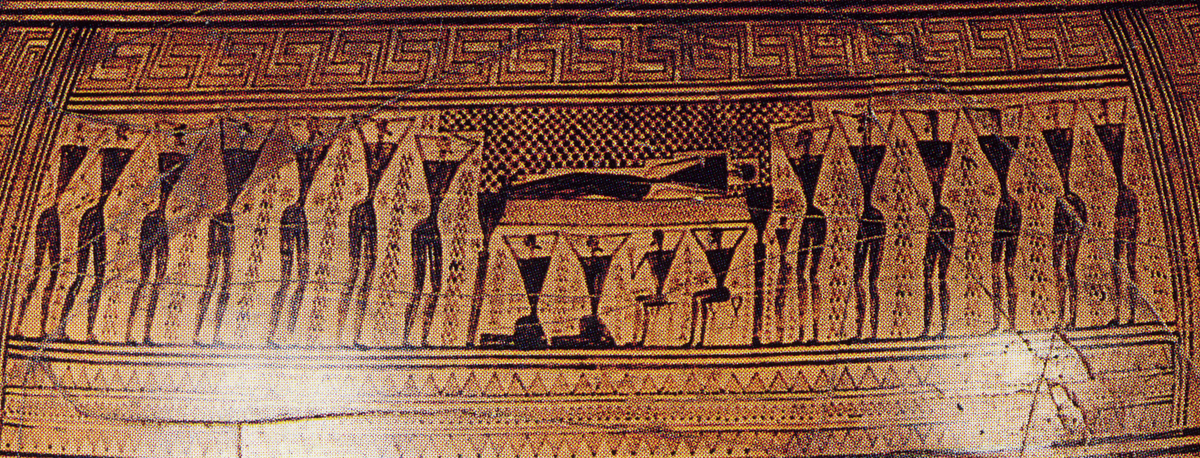

At the beginning of the Late Geometric period, circa 760 BC, some unique products of technological complexity appeared for the first time in Attic burials. These were the monumental Dipylon-style amphorae, the name of which was given after the recovery of the notorious vessel ‘Athens 804’ at the Kerameikos cemetery, close to the location of the ancient Dipylon gate.

Vessels of such class were over 1.5m tall and elaborately decorated with figurative and geometric representations. They functioned as grave markers and were produced for elite consumption at a time of increasing social competition, which was expressed through status display in burial rites.

Dipylon-style vessels associate with changes in the funerary practices of the Late Geometric period. Morris (1987) notes a shift from primary cremations to inhumations around c.760 BC, accompanied by the use of enlarged grave markers of the Dipylon tradition. At around c.700 BC there is a return to primary cremations in shaft graves; the use of ceramic grave markers stops abruptly; pottery and other luxury goods decline, while dedications move from graves to sanctuaries. This is when Morris (1987) places the beginning of the formation of the Athenian polis. In a more detailed study, Whitley (1991) argues against Morris (1987) that the complete breakdown of aristocratic order in Attica occurred c.735 BC, during the Late Geometric II period. During that time, there is less exclusivity in the consumption of exotica and ceramic forms in burials and pottery production is regulated by elite demands.

Connoisseurship and the study of Late Geometric workshops

The identification of workshops of the Dipylon tradition has been based solely on connoisseurship, which identifies painters and painter groups according to distinct patterns and repetitions in their drawing techniques.

A major study by Jean Davison (1961) identified 27 groups of Late Geometric ceramic workshops, the earliest of which attributed to the Dipylon Mater. More recently, Anne Coulié (2015) argued that the Dipylon workshop consisted of at least five individual artists: the Dipylon Master painter, three of his most accomplished students and a secondary student, who only decorated the handles. In my opinion, both approaches are problematic as they equate the painters with the workshops.

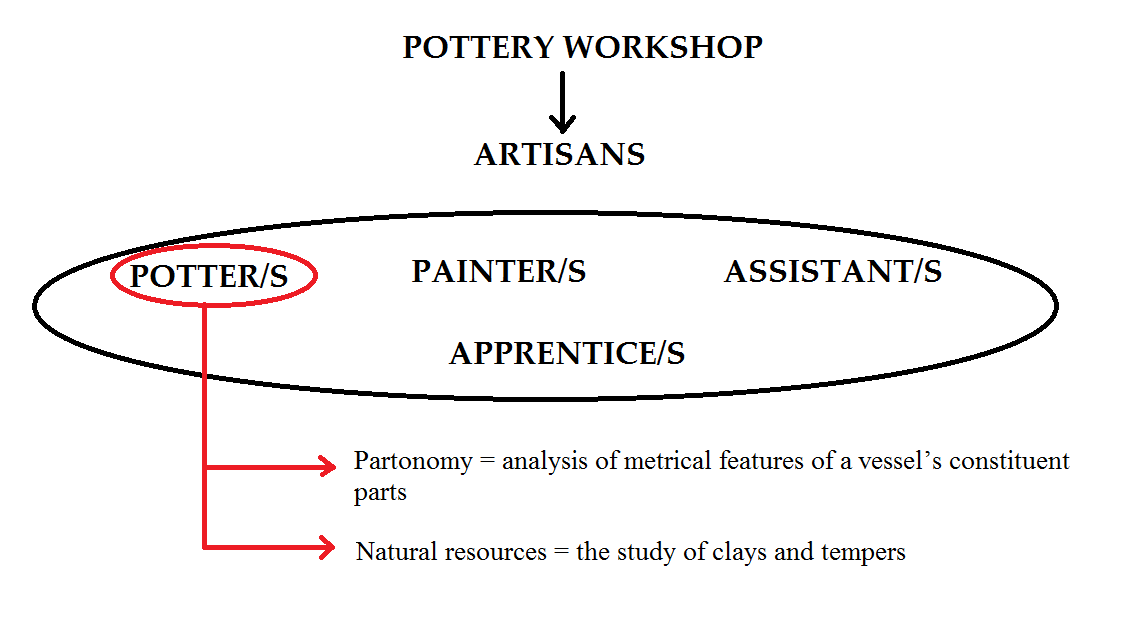

During my PhD research, I decided to bypass connoisseurship and introduce a different approach. I saw the painters as part of the total artisans working in Attic Geometric workshops and decided to focus on the potters instead. I followed the chaîne opératoire approached and examined partonomy, which is an analysis of metrical features of a vessel’s constituent parts, and secondly natural resources, which relates to the study of clays and tempers.

My research showed that the production of Attic Geometric amphorae was highly standardised all across two centuries, if not even earlier. I also argued that although the decoration of Late Geometric finewares is likely to be attributed to a number of different workshops or hands of individual painters, the standardisation of Attic Geometric amphorae suggests that their production was practised by a limited number of potters. The case of the Dipylon-style amphora, however, was distinct and during my PhD research, I purposely avoided discussing it in detail. The aim of this paper is to explore the diversity behind Attic Early Iron ceramic production and to address the ‘standardisation versus specialisation’ debate in relation a ceramic product designed exclusively for elite consumption in burial rites.

Methodology and argument

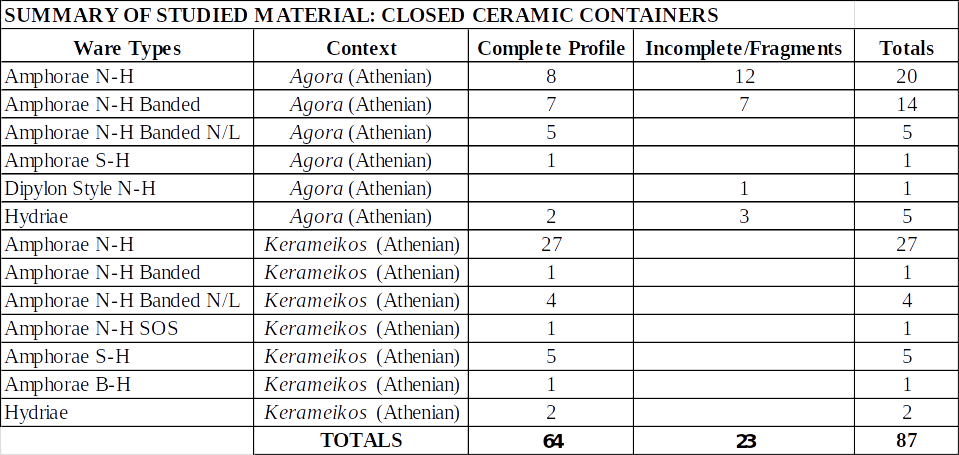

This paper compares various examples of Attic Geometric amphorae and a monumental Dipylon-style vessel in order to demonstrate their production differences. I argue that although typical classes of Geometric decorated amphorae were produced in a highly standardised manner, monumental vessels combined a number of features that were highly irregular for pottery production of that time.

The total material for this study numbers 64 vessels coming from a range of typologies: elaborately decorated neck-handled, belly-handled and shoulder-handled amphorae, banded neck-handled amphorae (some without necks), a single ‘SOS’ neck-handled amphora, and few plainly decorated hydriae. The total assemblage derives from three locations: the Athenian Agora, the Kerameikos cemetery and the Kynosarges burials.

Partonomy

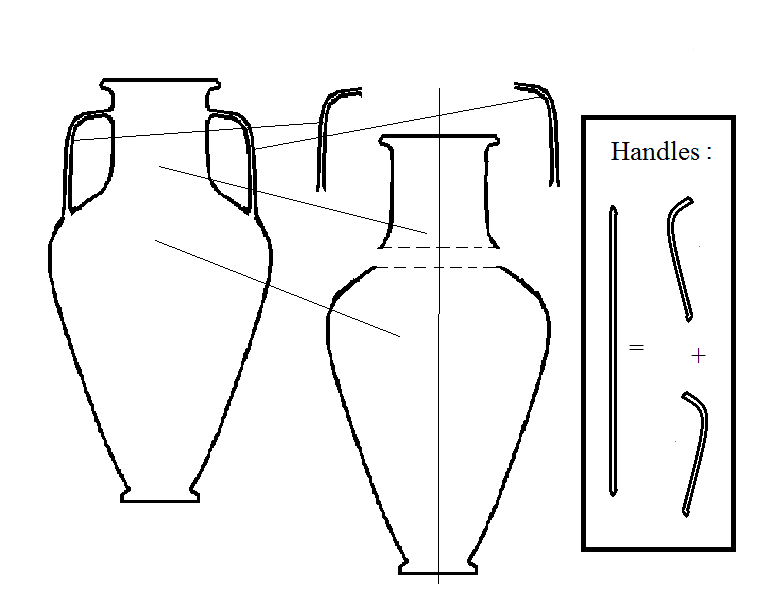

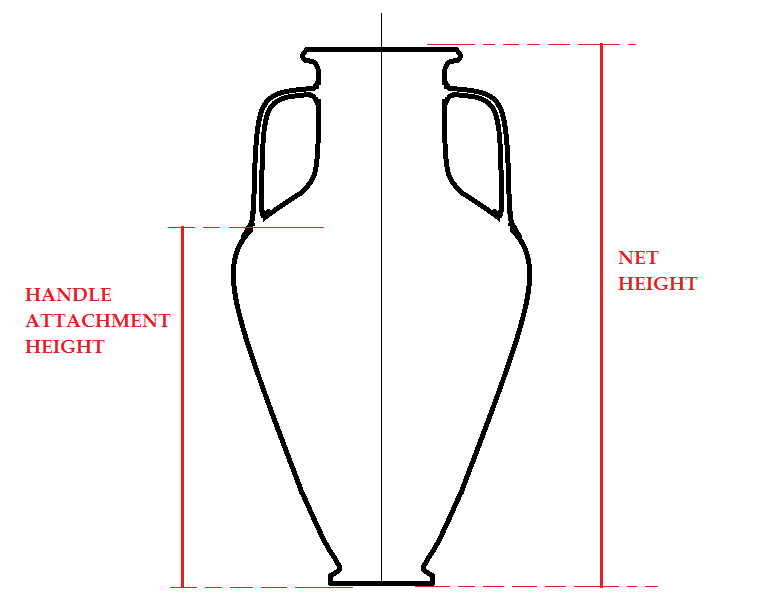

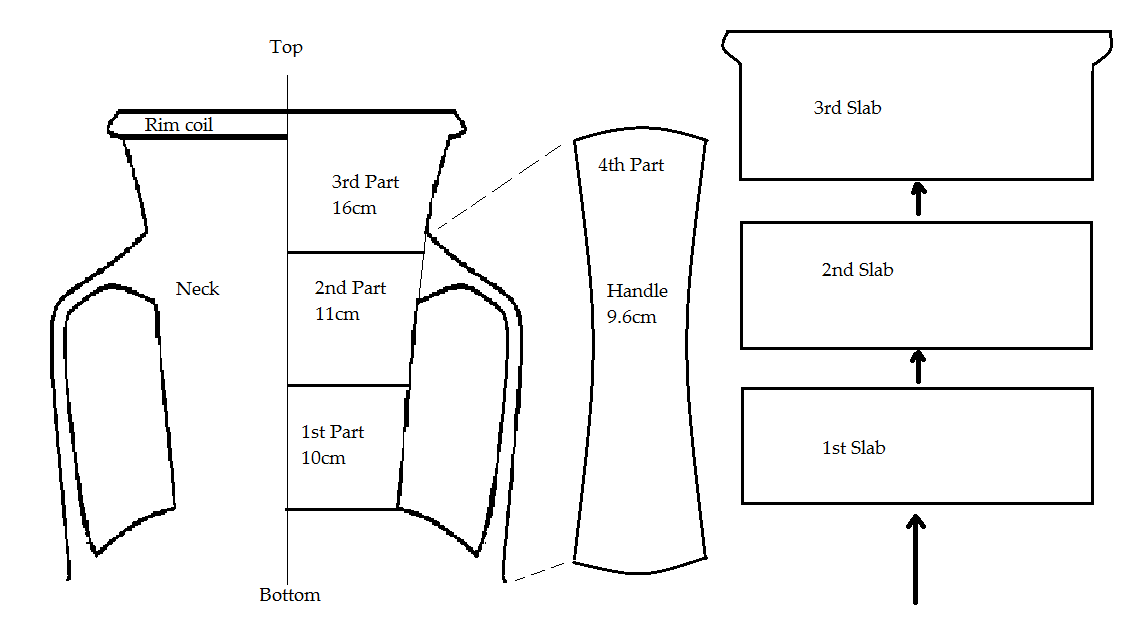

Partonomy is a term described by Van der Leeuw (1993, 136-7) and relates to the constituent parts of a complex vessel form. In relation to its partonomy, a standard Geometric amphora consists of at least four parts: main body, neck and two handles.

The identification of constituent parts is usually problematic. Even though the main bodies of most amphorae were built in one piece, some vessels were built in two pieces: one for the base and another for the lower body. An example of such partonomy is amphora P15838 from the Athenian Agora.

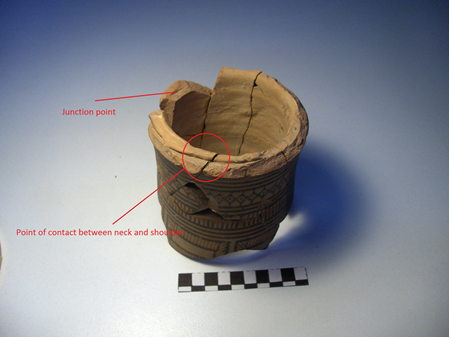

As opposed to bases, all amphora necks were definitely produced as separate parts and were attached on the shoulders of amphorae during a separate episode on the potter’s wheel. This attachment technique has left visible traces on neck fragment P8382 from the Athenian Agora.

By following these observations one can easily re-construct the sequence of production from the beginning. Geometric amphorae were made from bottom to top. Their main body was formed first in at least one large unit, although there are cases suggesting that this was performed in more than one episodes on the wheel’s head. During the second and third step of production, the potter formed the neck and then attached it on the vessel’s shoulders, actions that constitute two separate episodes on the wheel. Finally, during the fourth step, the potter formed and attached the handles after having removed the vessel from the wheel.

Figure 10: Building an amphora

Study of metrical features

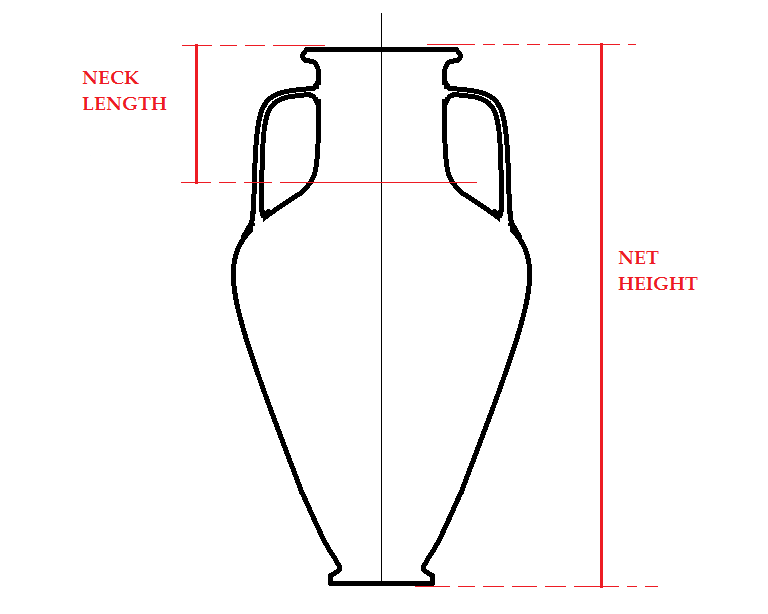

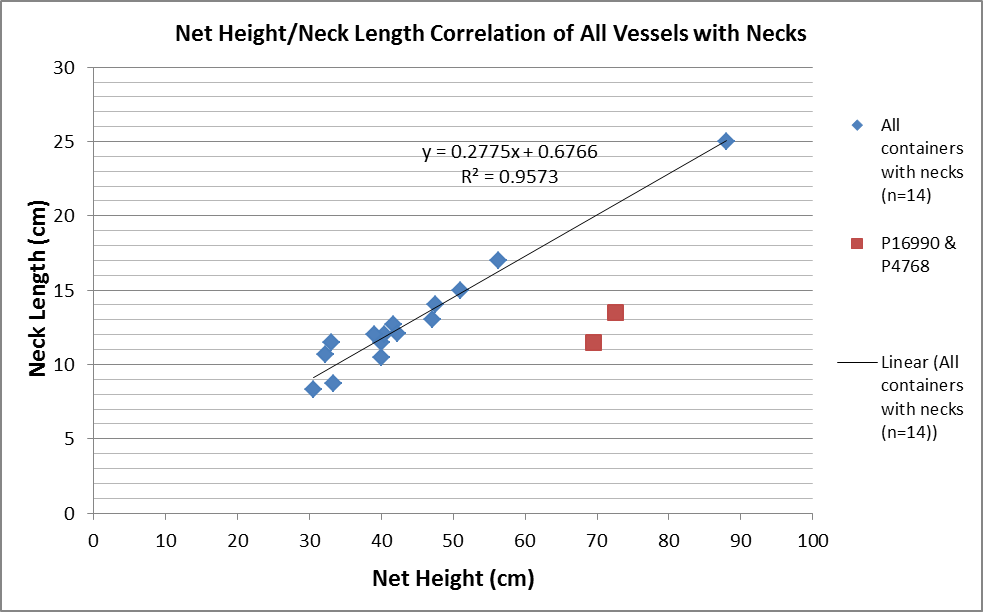

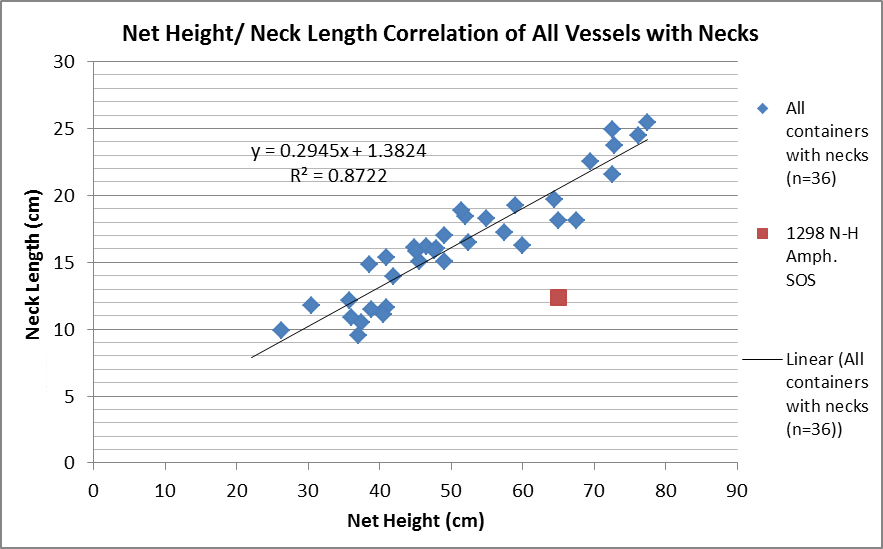

Standardisation in the production of Geometric amphorae is noted in the proportions between different vessels parts, which show that these have been assembled by following distinct patterns. The first pattern is noted in relation to the correlation of neck length and net vessel height.

The regression line for the Agora amphorae shows that neck lengths are roughly equal to 27.75% of a vessel’s net height. In a similar pattern, the regression line for the Kerameikos material shows that neck lengths are roughly equal to 29.45% of a vessel’s net height.

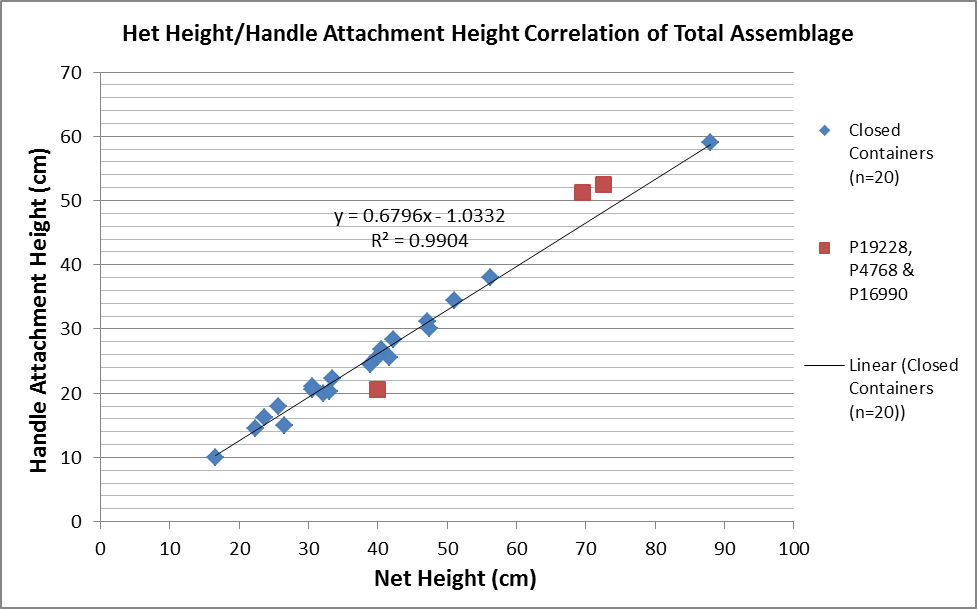

For both sites, the necks of all typological classes of amphorae have been conceptualised and produced at a proportion just below 30% of a vessel’s net height. A similar pattern is noted in relation to the correlation between handle attachment height and vessel net height.

For the Agora assemblage, the majority of vessels appear aligned. Handle attachment height of most typologies is roughly equal to 67.96% of a vessel’s net height. The same correlation for the Kerameikos pottery shows that for neck-handled amphorae, handles were attached at a height of roughly 66.67% of a vessel’s net height.

The regression lines for both sites show a deliberate choice and a strong technological tradition during which vessel handles were attached at a height of roughly 67%, or in other words close to a fraction of 2/3 (=66.67%), of a vessel’s net height.

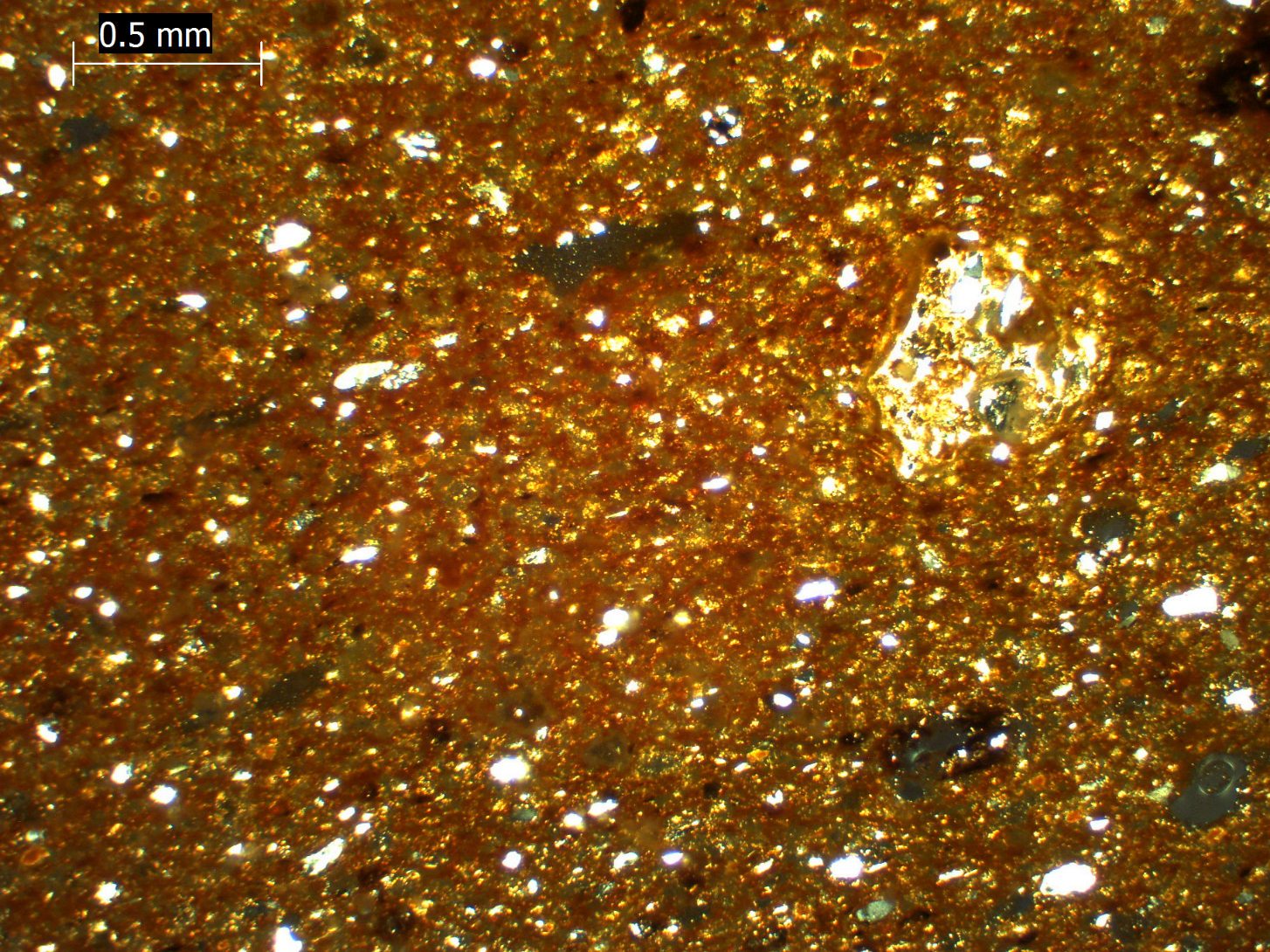

Study of fabrics

During my PhD research, a study of fabrics based on thin section microscopy showed standardisation in the production of Attic Geometric finewares, including large decorated amphorae. All vessels were made of the same fabric, which came it two relatively similar variants. Furthermore, the fabric of both large-sized amphorae and other smaller vessel classes was the same. Such fabric characterisations were further verified by a combination of scanning electron microscopy and x-ray diffraction tests.

The Dilylon-style amphora

A neck fragment with part of the shoulder and one handle, was the only monumental Dipylon-style artefact examined. In general, such finds are rare and access for their study is restricted.

The above vessel fragment is 46cm in height, 50.4cm in rim diameter, 1.3cm in minimum wall thickness and weighs roughly 14kg. The artefact reveals the complexity of the chaîne opératoire of large grave markers connected with burials and status display, and is completely different compared to all other vessels examined in this study.

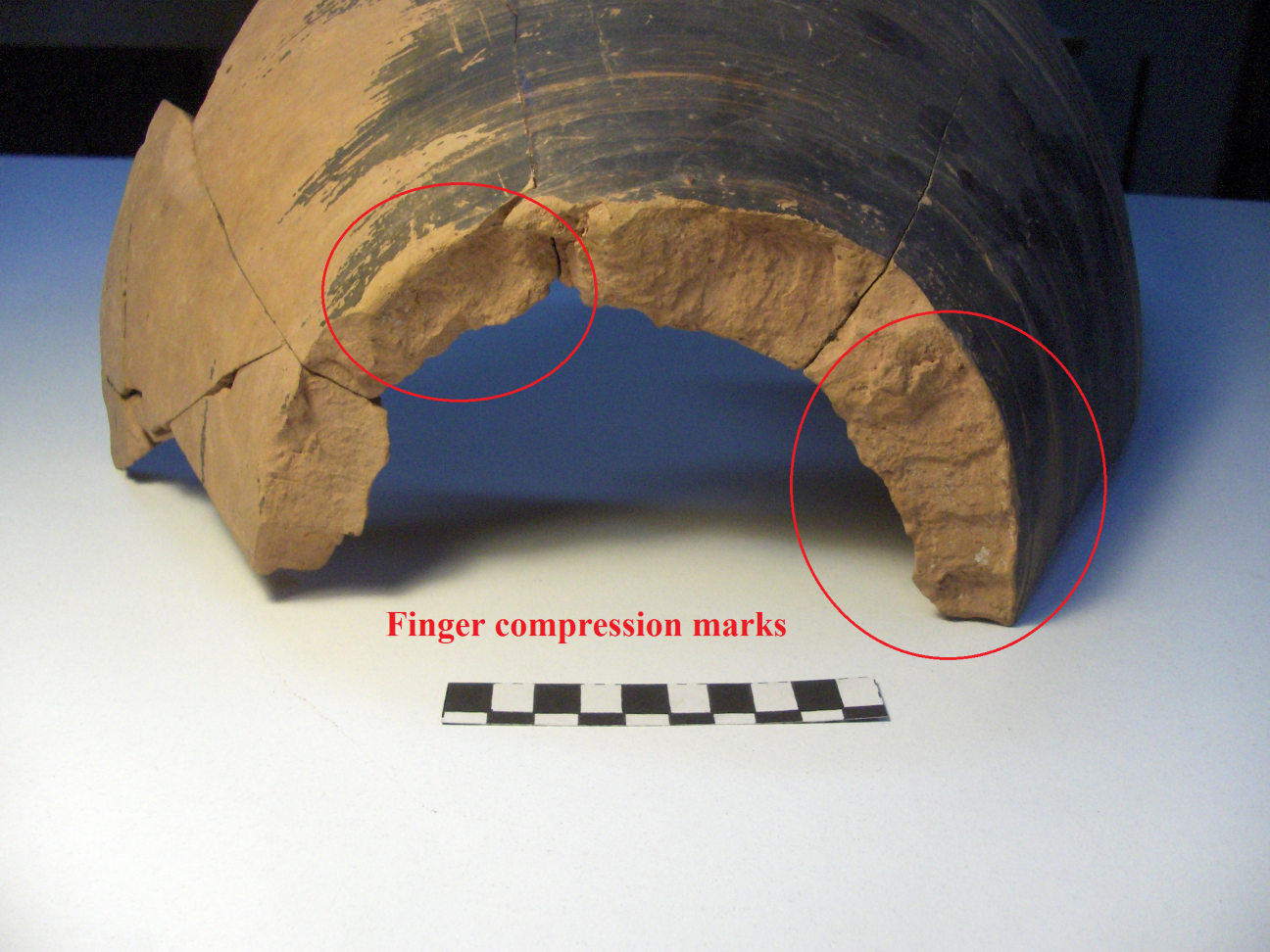

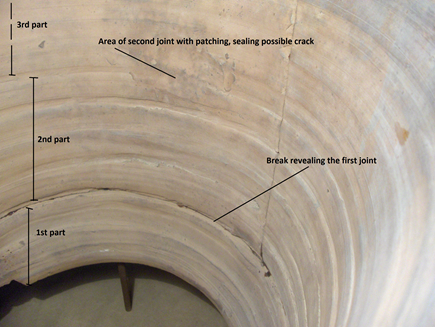

By contrast to the necks of standard amphorae, which were produced from a single piece of clay during a single episode on the wheel’s head, P22435 was produced in five (if not six) different parts that were assembled by a combination of techniques. Macroscopic analysis showed that the neck was produced of at least three clay cylinders, connected together by placing one on top of the other. The final product was assembled and finished on a wheel or turntable, where the potter stabilised the cylinders together, shaped the neck and formed the rim coil by pulling the clay outwards.

The interior surface of the neck fragment bears a vertical crack which is likely to suggest that the clay cylinders were not formed on a spinning wheel. Instead, it is likely that these were originally produced from rectangular slabs, which were curved into a cylindrical shape before attached together to form the neck. Furthermore, there are indications that such rectangular slabs were produced inside a mould and their manufacture could indicate similarities with tile production.

Thorough macroscopic analysis of the fragment’s interior shows two clear joints, which allow the estimation of width of the three clay slabs or cylinders that form the neck. Two of them, and also the handle of the vessel, are almost the same; therefore, it is likely that they were produced inside the same mould.

These observations lead to the paper’s final question: why is a Dipylon-style amphora the product of a different chaîne opératoire compared to other classes of contemporary amphorae? Firstly, it was produced by a combination of three techniques: moulding, hand-building, and ‘wheel’ finishing; it is not the product of wheel-throwing as it happens with other amphorae. Secondly, the use of moulds and its manufacture techniques show possible connections with tile production, which is a totally different chaîne opératoire. Thirdly, it is not the product of full-time workshop production. According to Eleni Hasaki (2002, 224) a Dipylon-style amphora could not fit inside an average Geometric kiln; it was probably fired on its own, which indicates seasonal production.

Another interesting point in relation to the different chaîne opératoire of Dipylon-style vessels relates to their weight. The weight of the neck fragment under discussion is c.14kg in fired state. If the neck is 25% of a vessels weight, then the total estimated weight for the entire vessel would have been c.56kg after firing. If there has been a 20% weight loss due to water evaporation during the drying stage (Rice 2005, 65-7), then the vessel’s gross weight would have been c.67.2kg before firing. This weight is impractical to manage on a wooden wheel, plus the amounts of energy required to spin that wheel would have been unconventional with the wheels technical features. This observation is likely to suggest that the production of Dipylon-style amphorae was not depended on wheel-throwing, despite the similarities of such vessels with other wheel-made equivalents.

Conclusions

Combining the above discussion with the study by Roux and Courty (1998) on wheel fashioning methods, and in relation to the analysis of apprenticeship duration in mastering wheel throwing techniques by Roux and Corbetta (1989), it appears likely that the production of monumental Dipylon-style vessels was in the hands of experienced potters, who employed combinations of techniques in order to achieve the expected results. Such potters were probably competent in managing the potter’s wheel; however, they were experienced enough not to depend on it. In fact, such potters were most likely multi-skilled professionals, with experience in the manufacture of different types of baked-clay materials. Finally, the complexity of the production of such vessels probably required the collaboration of a number of artisans; therefore, monumental vessels were most likely produced by a limited number of large and highly specialised workshops.

Bibliography

Davison, J.M., 1961, Attic Geometric Workshops, Yale Classical Studies 16, New Haven (CT): Yale University Press.

Coldstream, J.N., 1968, Greek Geometric Pottery, London: Methuen & Co.

Coulié, A., 2015, ‘L’atelier du Dipylon: style, typologie et chronologie relative”, in ed. Vlachou, V. (ed.) Pots, Workshops and Early Iron Age Society: Function and Role of Ceramics in Early Greece. Proceedings of the International Symposium Held at Université libre de Bruxelles, 14-16 November 2013, Brussels: CReA-Partimoine, 37-48.

Hasaki, E., 2002, Ceramic Kilns in Ancient Greece: Technology and Organization of Ceramic Workshops, Unpublished PhD Thesis, Cincinnati (OH): University of Cincinnati.

Morris, I., 1987, Burial and Ancient Society: The Rise of the Greek City-State, Cambridge: Cambridge University Press.

Rice, P.M., 2005, Pottery Analysis: a Sourcebook, 2nd edition, Chicago (IL): University of Chicago Press.

Roux, V. and Corbetta, D., 1989, The Potter’s Wheel: Craft Specialization and Technical Competence, New Delhi: Oxford & IBH.

Roux, V. and Courty, M.A., 1998, ‘Identification of wheel fashioning methods: technological analysis of 4th–3rd Millennium BC Oriental ceramics’, Journal of Archaeological Science (25), 747-63.

Van Der Leeuw, S., 1993, ‘Giving the potter a choice. Conceptual aspects of pottery techniques’, in Lemonnier, P. (ed.) Technological Choices: Transformation in Material Cultures Since the Neolithic, London and New York (NY): Routledge, 238-88.

Whitley, J., 1991, Style and Society in Dark Age Greece. The Changing Face of a Pre-literate Society, 1100- 700 BC, Cambridge: Cambridge University Press.